Electroless Nickel Plating

About Electroless Nickel

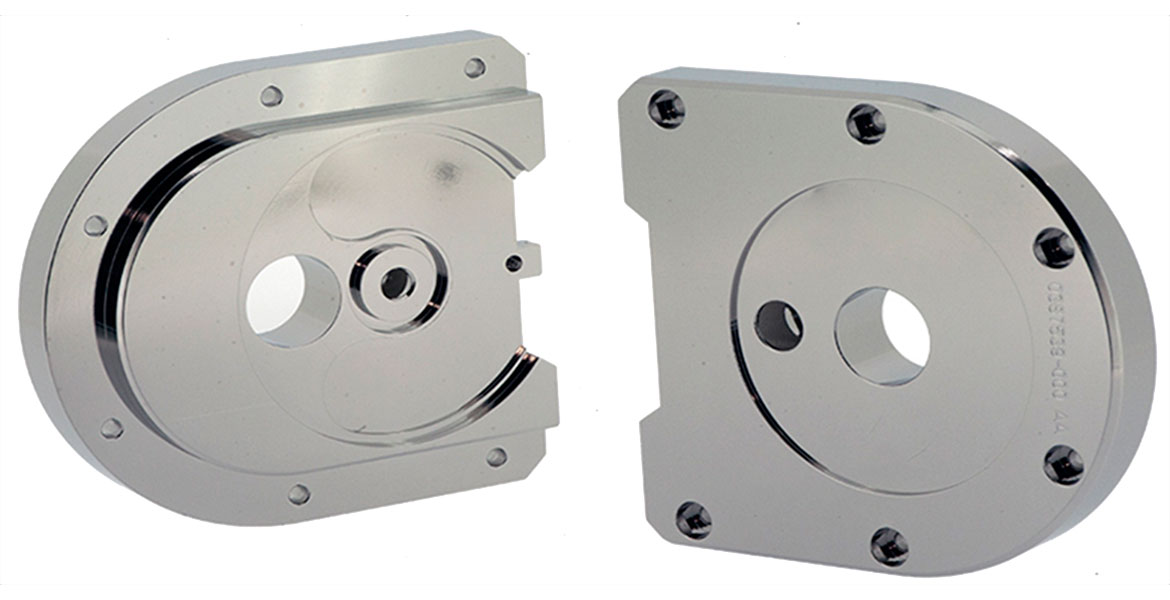

Electroless nickel plating is an auto-catalytic chemical technique used to deposit a coatin)g of nickel-phosphorus or nickel-boron on a solid part. The process relies on the presence of a reducing agent, which reacts with the metal ions to deposit metal. Unlike electroplating, it is not necessary to pass an electric current through the solution to form a deposit. This plating technique is to prevent corrosion and wear. Electroless nickel plating has several advantages versus electroplating. Free from flux-density and power supply issues, it provides an even deposit regardless of workpiece geometry, and with the proper pre-plate catalyst, can deposit on non-conductive surfaces

A feature of great importance in all applications for electroless nickel is the ability to produce deposits with a very high degree of thickness uniformity.

Corrosion Resistance

Electroless nickel is commonly used in engineering coating applications where wear resistance, hardness and corrosion protection are required. Electroless nickel exhibits corrosion resistance against ammonia, sea water, brine, organic acids and reducing inorganic acids. Therefore, it has many applications in such industries as food, chemical, and oil.

Types of Electroless Nickel Plating

Medium phosphorus Electroless nickel

Medium phosphorus treatment has a high speed deposit rate and offers bright and semi-bright options for cosmetic particularization. The processing is very stable. This is the most common type of Electroless nickel applied.

Advantages of Electroless Nickel Plating

- Does not use electrical power

- Even coating on parts surface can be achieved.

- There is flexibility in plating volume and thickness.

- The process can plate recesses and blind holes with stable thickness.

- Chemical replenishment can be monitored automatically

- Complex filtration method is not required

- Matte, Semi Bright or Bright finishes can be obtained.

- Sources: https://en.wikipedia.org/wiki/Electroless_nickel_plating, https://nickelinstitute.org